CONTACT

System 180 GmbH

Ernst-Augustin-Straße 3

12489 Berlin

Telephone: 030 . 788 58 41

Fax: 030 . 787 09 160

SERVICE

Our values “Sustainable Development Goals”

Economy and the environment must go hand in hand – that is our credo. To implement this principle, we rely on an environmental management system in accordance with EMAS (Eco-Management and Audit Scheme). Established by the European Commission in 1993, EMAS is considered the most demanding environmental management system in the world.

Through our certification according to EMAS, we make an effective contribution to environmental protection, save costs and take social responsibility. EMAS ensures legally compliant and transparent implementation of all environmental aspects, from energy consumption to waste and emissions management.

However, our company goes beyond mere fulfillment of environmental regulations. In our environmental statement we publicly provide detailed information on our environmentally relevant activities and make data available. This includes, for example, information on emissions, waste management, biodiversity as well as water and energy consumption.

We are proud to meet the highest standards in environmental management with EMAS and to continuously improve our environmental performance. It is only through joint efforts that the economy and the environment can coexist in harmony and enable a sustainable future.

We consider open innovation through knowledge transfer to be an essential contribution for creating a sustainable future. Findings from collaborations and the lively exchange through networking are continuously incorporated into our improvement processes. Our proven furniture series Design Thinking Line, for example, is the result of our close cooperation with the Hasso Plattner Institute and stands for agility and sustainability.

Continuous innovation is a fundamental part of our corporate philosophy. In intensive research work we dedicate ourselves specifically to sustainability topics. For many years we have been driving the marketability of bio-based material innovations and substitutes through our participation in various research consortia, including partners such as the Fraunhofer Institute, Technical University of Berlin, Eberswalde University for Sustainable Development and many more.

Under the leadership of the Fraunhofer IAP and accompanied by the Eberswalde University for Sustainable Development, System 180 is currently participating in the joint research project ReSpan as an application partner. The aim of the project is to develop a closed recycling process for wood-based materials. This would enable us to introduce another product line made of recycled material as an alternative to the MdF material used.

Timeless design and timeless aesthetics

High-quality, durable materials

Mobility

Modularity

Concept of upgradeability

Conversion options

Remanufacturing

Refurbishment

Remanufacturing

Dismountability

Recyclable

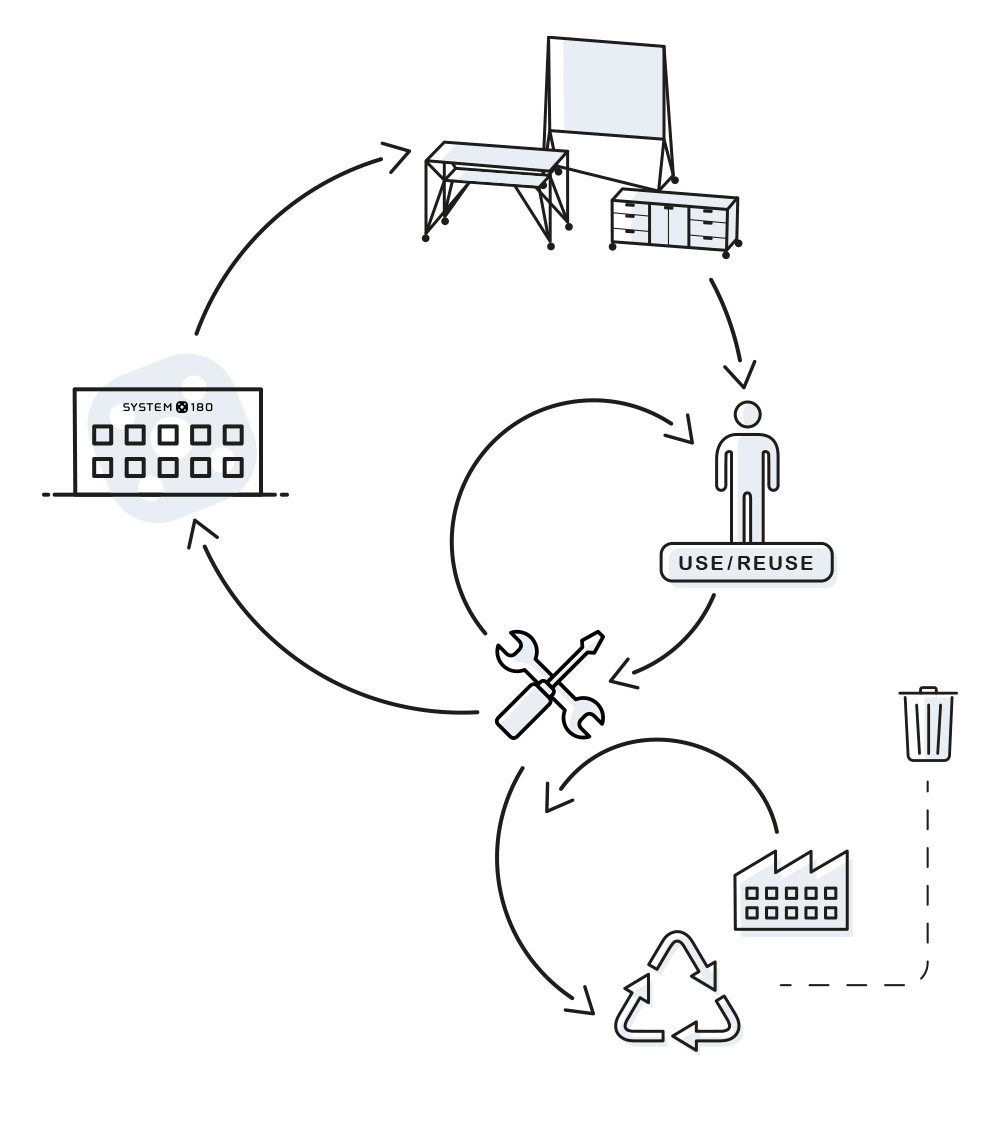

Agility and ecodesign form a sustainable synergy in our furniture. As an enabler of New Work, the System 180 portfolio promotes innovative forms of work for the future. Thanks to agile features, our configurations offer maximum flexibility for dynamic growth through expandable functionality. Modularity enables individual and situational adjustments. All modules of our modular furniture system can be easily exchanged and converted. Key to the future viability and value retention of our products are durable design, time-resistant aesthetics, the use of high-quality materials, such as extremely robust stainless steel, and the anticipation of various usage scenarios. We strive for user-centered and long-term solutions, in accordance with the principle of Design Thinking. Sustainable service packages support an extension of lifecycle phases such as the fact usage period in the sense of circularity. System 180 offers, among other services, individual upgrades and develops offers for subsequent use through refurbishment and remanufacturing.

System 180 develops and manufactures 100% in Berlin. Our site is supplied with green electricity and climate-friendly district heating. Home-generated solar energy already covers 20% of our energy needs. A green roof area of 2,000 m² contributes to the improvement of the macroclimate. Precipitation on the site is drained in cesspools and directly used for groundwater recharge. We continuously optimize the resource efficiency of our manufacturing processes and pay attention to sustainable material ecology and recycling. Offcuts are reduced to a maximum and steel waste is recycled completely without loss in the material cycle. Only energy but no water is used in the resource-saving production of system pipes. In these processes we only emit noise, but no air pollution. Our logistics are handled by regional service providers using recyclable packaging, which itself is recycled.

Thanks to our local production, we promote local jobs. In cooperative collaboration, we live a mission-oriented and transparent corporate culture. We place the issue of sustainability at all levels and in all areas. New Work is a pillar of our product range, but also of our own working methods. Employees from all departments are integrated and supported holistically in decision-making processes. At System 180, we are actively committed to inclusion and anti-discrimination. We welcome diversity as an indispensable added value for our teamwork. We always welcome cooperation with non-profit organizations.